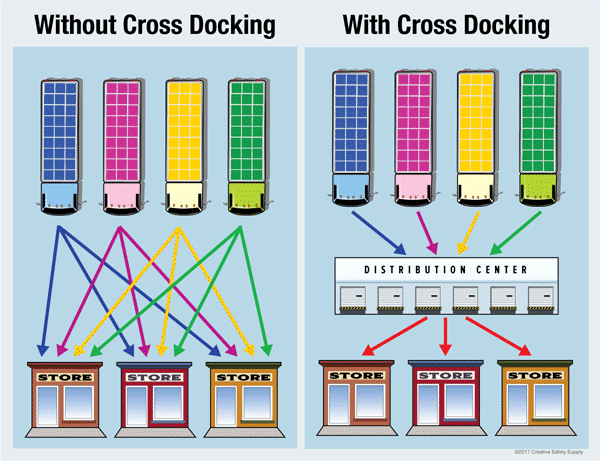

Cross-docking is a service in the logistics sector of unloading materials from an incoming trailers, trucks or shipping containers and then either short term storage or directly loading these materials onto outbound vehicles with little storage in between.

This may be done in order to change the type of quantity of goods, to sort material intended for different destinations, or to combine material from various origins into haulage vehicles or into containers with the same or similar destinations.

Image credit to Creative Safety Supply

Image credit to Creative Safety Supply

Cross-dock operations are particularly prominent inside sea ports and have been in constant use in less-than-truckload (LTL) operations ever since.

The Logistics Terminal in Tilbury Port shows a good example of cross docking operations where oranges and palletised biscuits come in from all over the world in containers or on trailers and are immediately trans shipping and cross docked onto outbound lorries.

In the transport industry in Great Britain, cross-docking is done by offloading cargo from one transport vehicle or shipping container directly onto another, with minimal or no warehousing.

In practice, cross-docking operations may be used as staging areas where inbound materials can be sorted, consolidated, and stored short term until the outbound shipment is complete and ready to send via road.

1. "Hub and spoke" operations, where goods are brought in to a central location and then sorted for delivery to a variety of destinations would be a typical application of cross docking

2. Consolidation arrangements, where a number of smaller shipments are combined into a single larger shipment for economy of transport to a single destination or multiple destinations.

3. Deconsolidation arrangements, where large shipments such as full loads are broken down into smaller loads for ease of delivery on smaller vehicles. This is particularly useful for deliveries into congested cities like London.

- Cross-docking can depend on constant communication between suppliers, distribution facilities, and all points of sale.

- Customer and supplier geography, particularly when a single corporate customer has many multiple branches or using points

- Transport costs for the commodities being delivered to multiple locations or for multiple types of goods delivered to a single branch.

- Complexity of cargo. If a client has multiple types of cargo coming from all over the world and they want a full load delivered to a depot then cross docking is the solution.

- Handling this material well is essential as material needs to be loaded properly to avoid movement on route and potential damage to goods.

- Tracking of inventory whilst at the warehouse facility or in transit is essential.

Cross-docking is a great tool to have in your logistics chain. This service can be a key differentiator between you and your client.

Cross-docking reduces the square footage needed in a facility. Because little to no storage occurs, only a small amount of space is needed for this activity, significantly reducing the footprint of a facility and the associated costs.

Because little to no storage occurs in cross-docking facilities, the costs related to storing your goods is also reduced.

In conjunction with this reduction in storage costs, material handling also sees significant reductions. Material handling is limited to loading, staging and unloading with minimal picking and put away activity.

With cross-docking a warehouse can assist in managing and improving customer product quality. During the unloading and staging process staff can easily inspect inventory for damage incurred during transit. This can help to reduce the amount of damaged inventory that reaches customers and help improve customer satisfaction rates.

The reduction of material handling needs leads directly to the labour cost savings associated to these activities. This allows your business to pass on savings to clients, providing an extra competitive advantage related to cost.

Because the number of handling requirements on each inventory item is reduced due to lack of storage and minimal handling, the probability of damage to inventory and the costs associated with this are also significantly reduced.

Utilizing cross-docking also assists in the reduction of delivery times. Typically facilities offering these services are located in geographical areas that are near the final delivery destination. This helps to reduce delivery times by eliminating excess travel.

Cost savings, increased product quality and reduced delivery times due to cross-docking also factor in to help increase customer service satisfaction. This will help to retain current customers and capture additional market share.

The utilization of cross-docking can help to reduce transportation costs. With optimized routing, less miles are wasted, reducing fuel and associated vehicle service costs.

Lastly, cross-docking provides fixed asset cost savings. Cross-docking requires less facility square footage.

All of these benefits show one key issue: implementing cross-docking can provide your company with many new opportunities to save money, increase efficiency and better serve clients.